Index

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for Spacecraft Manufacturing

GAO Helps customers Comply with Standards, Mandates & Regulations of Spacecraft Manufacturing

GAO Software Provides Easy Integration with API

Case Studies of RFID Applications

Related Products & Systems on Other Pages on This Website

Employee & Attendance Access Control System

Work In Process WIP Asset Tracking System

BLE | Bluetooth Low Energy | BLE Gateways & Beacons – GAO RFID

RFID Readers | Buy RFID Readers | RFID Reader Writers – GAO RFID

RFID Tags | Buy RFID Tags – GAO RFID

On Metal RFID Tags – All Types

Overview

Spacecraft manufacturing industry involves the design, development, and production of spacecraft for various purposes, such as scientific research, commercial satellite communication, and military defense. This industry is highly specialized and technically advanced, requiring expertise in various engineering disciplines and significant investments in resources. Spacecraft manufacturing companies work with clients to develop spacecraft tailored to their specific needs and requirements.

GAO’s RFID, BLE, IoT, and drone technologies have helped its customers in the space craft manufacturing industry to improve their work processes, their operations and productivity by better management of their staff, materials and operational equipment such as cleanrooms, CNC machines,3D printers, CNC lathes and mills, thermal vacuum chambers, environmental test chambers, integration and testing facilities, robotics and automation systems, payload integration equipment.

Ranked as a top 10 global RFID supplier and based in New York City and Toronto, GAO RFID Inc offers a wide choice of RFID (radio frequency identification) readers and tags at ultra high frequency (UHF), high frequency (HF, including NFC) and low frequency (LF), BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. Such RFID and BLE products and systems, together with its IoT and drone technologies, have been widely used in spacecraft manufacturing industry.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for Spacecraft Manufacturing

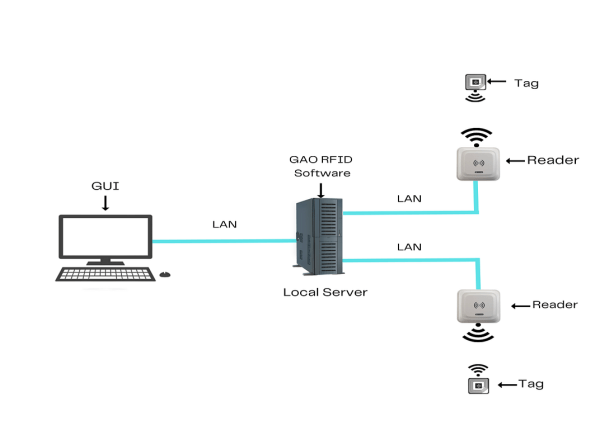

To satisfy its customers, GAO’s RFID or RFID Systems for spacecraft manufacturing industry are offered in 2 versions. One version is that its software is running on a local server, and another version is that its software runs in the cloud. The above illustrates GAO system for spacecraft manufacturing with its software running on a local server.

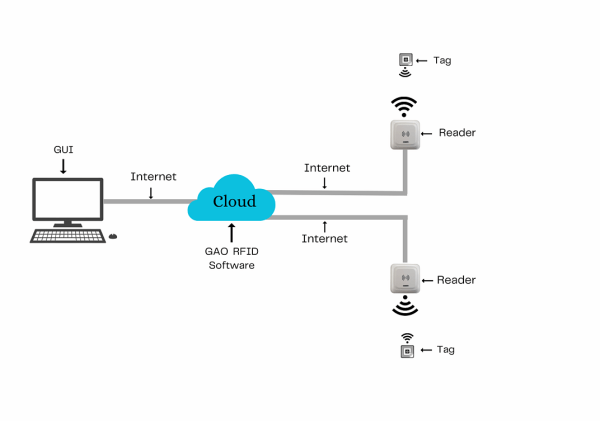

The above illustrates GAO system for spacecraft manufacturing with its software running in cloud.

GAO’s RFID technologies bring the many benefits to spacecraft manufacturing industry:

- Improved Inventory Management: GAO’S RFID tags can be attached to components and materials, allowing for real-time tracking and monitoring of inventory levels. This can help manufacturers reduce waste, avoid shortages, and optimize their supply chain.

- Enhanced Quality Control: Our RFID technology can be used to monitor and track each stage of the manufacturing process, from raw materials to finished products. This can help manufacturers identify defects and quality issues early in the process, reducing the risk of costly errors.

- Increased Efficiency: Our RFID tags can be used to automate many tasks in the manufacturing process, such as tracking and routing components and materials. This can help manufacturers reduce the time and labor required to complete each task, leading to faster production times.

GAO’s BLE technologies offer longer reading range and particularly attractive for applications with larger work spaces within spacecraft manufacturing industry:

- Improved Asset Tracking: GAO’s BLE beacons can be used to track the location of assets, such as tools and equipment, throughout the manufacturing process. This can help manufacturers reduce losses and improve maintenance and repair processes.

- Enhanced Worker Safety: Our BLE technology can be used to monitor worker safety, such as detecting when a worker enters a hazardous area or when they fall. This can help improve safety in the manufacturing facility.

- Increased Efficiency: Our BLE technology can be used to automate many tasks in the manufacturing process, such as tracking and routing components and materials. This can help manufacturers reduce the time and labor required to complete each task, leading to faster production times and increased efficiency.

- Improved Maintenance and Repair Processes: GAO’s BLE technology can also be used to monitor the status of equipment and assets in real-time, allowing manufacturers to perform preventative maintenance and repairs before equipment fails.

GAO’s RFID and drone technologies are often combined and such solutions offer the following benefits to spacecraft manufacturing industry:

- Improved Inventory Management: GAO’s RFID tags can be attached to components and materials, allowing for real-time tracking and monitoring of inventory levels

- Increased Efficiency: The Drones can be used to automate many tasks in the manufacturing process, such as delivering materials and components to workers on the manufacturing floor.

- Improved Quality Control: The Drones equipped with cameras and sensors can be used to inspect components and finished products, identifying defects and quality issues early in the manufacturing process.

Here are benefits of GAO’s IoT technologies to spacecraft manufacturing industry:

- Improved Asset Tracking: GAO’s IoT sensors can be used to track the location of assets, such as tools and equipment, throughout the manufacturing process.

- Enhanced Worker Safety: Our IoT sensors can be used to monitor worker safety, such as detecting when a worker enters a hazardous area or when they fall.

- Increased Efficiency: Our IoT sensors can be used to automate many tasks in the manufacturing process, such as tracking and routing components and materials.

GAO Helps Customers Comply with Standards, Mandates & Regulations of Spacecraft Manufacturing

GAO RFID Inc. has helped many companies in spacecraft manufacturing industry to deploy RFID, BLE, IoT and drone systems and to ensure such deployments complying with the applicable industry standards, mandates and government regulations:

RFID, BLE, IoT, & Drone Standards & Mandates:

- NASA-STD-6002: This is a standard developed by NASA for the use of RFID technology in the aerospace industry. It provides guidelines for the use of RFID in various applications, including inventory management, asset tracking, and logistics.

- MIL-STD-129P: This is a U.S. Department of Defense standard that provides requirements for the labeling and tracking of military assets. It includes guidelines for the use of RFID technology for asset tracking and inventory management.

- SAE AS5678: This is a standard developed by the Society of Automotive Engineers (SAE) for the use of RFID technology in the aerospace industry. It provides guidelines for the design and implementation of RFID systems for tracking and managing inventory, assets, and components.

- ATA Spec 2000: This is a standard developed by the Air Transport Association (ATA) for the management of aircraft parts and materials. It includes guidelines for the use of RFID technology for tracking and managing inventory and assets in the aviation and aerospace industries.

- RTCA DO-362: This is a standard for the safety and certification of UAS. It provides guidelines for the development and certification of UAS for use in the aerospace industry.

- FAA Part 107: This is a regulation issued by the Federal Aviation Administration (FAA) for the commercial operation of drones in the United States. It includes guidelines for the use of drones in the aerospace industry.

US. Government Regulations:

- National Aeronautics and Space Act (1958): This law established NASA and gave it the responsibility for the civilian space program in the United States.

- Commercial Space Launch Act (1984): This law created a regulatory framework for the commercial space industry, including licensing requirements for space launches and reentries.

Canadian Government Regulations:

- Canadian Space Agency Act (1990): This law established the Canadian Space Agency (CSA) and gave it the responsibility for the civilian space program in Canada.

- Remote Sensing Space Systems Act (2005): This law regulates the operation of Earth observation satellites and the collection, distribution and use of remote sensing data in Canada.

National Aeronautics

and Space Act

Bluetooth Low

Energy(BLE):

Commercial Space

Launch Act (1984)

IEEE 802.15.1

MIL-STD-129P

RTCA DO-362

SAE AS5678

FAA Part 107

ATA Spec 2000

Canadian Space

Agency Act (1990)

NASA-STD-6002

Remote Sensing

Space Systems Act (2005):

GAO Software Provides Easy Integration with API

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions, and offers an API to the important systems in spacecraft manufacturing industry such as:

- Personnel management: Personnel management refers to the management of human resources involved in spacecraft manufacturing. It includes tasks such as workforce planning, recruitment, training, performance tracking, and employee development.

- Equipment management: Equipment management involves the effective management of the tools, machinery, and equipment used in spacecraft manufacturing. It includes tasks such as maintenance, calibration, procurement, and tracking of manufacturing equipment.

- Access control: Access control refers to the implementation of security measures to control physical and logical access to spacecraft manufacturing facilities and sensitive information. It involves measures such as biometric authentication, keycards, and surveillance systems to ensure that only authorized personnel can access restricted areas and data.

- Warehouse management: Warehouse management focuses on efficiently managing inventory, storage, order fulfillment, and logistics within spacecraft manufacturing facilities. It includes tasks such as inventory tracking, warehouse layout optimization, order processing, and quality control.

- Supply chain management: Supply chain management involves managing the flow of materials, components, and information from suppliers to spacecraft manufacturing facilities. It encompasses tasks such as supplier relationship management, demand forecasting, logistics, and risk management to ensure a smooth and efficient supply chain.

- Other applications: Other applications in spacecraft manufacturing include quality management systems, environmental health and safety (EHS) management, data analytic, and document management. These applications involve implementing systems and processes to ensure adherence to quality standards, compliance with safety regulations, analysis of manufacturing data, and efficient document control and storage.

GAO has enabled its customers to make use of some of leading software and cloud services in spacecraft manufacturing industry. Below are some of popular software and cloud services in spacecraft manufacturing industry.

- Autodesk AutoCAD: A widely used CAD software for creating 2D and 3D designs with robust drafting and modeling capabilities.

- IBM Rational DOORS: A requirements management software for capturing, analyzing, and managing product requirements.

- Atlassian Jira: A project management and issue tracking software that can be customized for configuration management and document control.

- Dassault Systèmes ENOVIA – a product life cycle management software platform that helps manage product data and processes, including design, engineering, and supply chain management.

- OpenRocket: An open-source rocket design and simulation software that helps users analyze the flight characteristics of rockets.

- HyperSizer: A software tool used for optimizing and analyzing composite and metallic structures, ensuring they meet performance and weight requirements.

- PTC Windchill: A product life cycle management software platform that helps manage product data and processes, including design, engineering, and supply chain management.

- Microsoft Azure: A cloud computing platform that offers services such as virtual machines, storage, and analytic, which can be used for spacecraft design, simulation, and analysis.

- Arena Solutions: A cloud-based PLM and quality management software for managing product development and manufacturing processes.

- MSC Nastran: A finite element analysis (FEA) software for structural analysis and optimization.

- Google Cloud Platform: A cloud computing platform that offers services such as storage, machine learning, and data analytic, which can be used for spacecraft design.

Autodesk AutoCAD

IBM Rational DOORS

Atlassian Jira

Dassault Systèmes

OpenRocket

HyperSizer

PTC Windchill

Microsoft Azure

Arena Solutions

ANSYS SpaceClaim

MSC Nastran

Google Cloud

GAO has worked with some of the leading technology companies in spacecraft in to provide integrated its RFID, BLE, IoT and drone solutions to customers. Here are some of the technology leaders in spacecraft manufacturing industry:

- Blue Origin: Blue Origin is a private aerospace manufacturer and spaceflight services company founded by Jeff Bezos. They focus on developing reusable rocket technology and have designed spacecraft like New Shepard and New Glenn for human spaceflight and satellite launches.

- Honeywell Aerospace: A company that offers a range of aerospace products and services, including avionics, engines, and advanced materials for spacecraft manufacturing.

- Lockheed Martin Space: A company that specializes in developing and manufacturing spacecraft and associated technologies, such as propulsion systems, communication systems, and thermal management systems.

- Northrop Grumman Space Systems: A company that provides space-based solutions, such as spacecraft design and manufacturing, satellite communication systems, and space exploration technologies.

- Thales Alenia Space: A company that specializes in designing and manufacturing spacecraft, including satellites, probes, and lander, as well as associated technologies, such as communication systems, navigation systems, and scientific instruments.

- L3Harris Technologies: L3Harris Technologies is a global aerospace and defense technology company. They offer a range of electronic solutions for spacecraft manufacturing, including communication systems, avionics, and sensor technologies.

- Sierra Nevada Corporation: Sierra Nevada Corporation (SNC) provides system technologies for spacecraft manufacturing. They offer integrated systems for spacecraft and space systems, including command and control systems, data processing systems, and payload integration systems.

- Harris Corporation: Harris Corporation (now part of L3Harris Technologies) is a global technology company that provides system solutions for the aerospace industry. They offer system technologies such as communication systems, navigation systems, and mission management systems for spacecraft manufacturing.

- Airbus Defense and Space: A company that offers spacecraft and satellite solutions, as well as associated technologies, such as communication systems, navigation systems, and scientific instruments.

- Raytheon Intelligence and Space: A company that specializes in providing advanced technologies and solutions for the aerospace and defense industry, including spacecraft and satellite solutions, as well as communication systems, sensors, and electronic warfare systems.

- General Dynamics Mission Systems: A company that provides advanced technologies and solutions for the aerospace and defense industry, including spacecraft and satellite solutions, as well as communication systems, sensors, and electronic warfare systems.

Blue Origin

Honeywell Aerospace and Defense

Lockheed

Martin Space

Northrop

Grumman

Space Systems

ThalesAlenia

Space

L3Harris Technologies

Sierra

Nevada

Corporation

Harris Corporation

Airbus Defence

and Space

Raytheon Intelligence

and Space

General Dynamics

Mission Systems

Case Studies of RFID Applications

Below are some RFID application cases in spacecraft manufacturing industry:

Trimble Inc: A spacecraft manufacturing company Implemented an asset tracking and management for RFID tags on various manufacturing equipment and components. Each tag contains unique identification information. RFID readers are installed at different checkpoints throughout the manufacturing facility to track the movement and location of assets.

Avigilon: Implemented a personnel safety and security RFID-enabled access control systems in spacecraft manufacturing facilities. Employees are provided RFID-enabled badges or cards for secure access to restricted areas.

Zebra: Implemented a reduced equipment loss UHF-RFID System enables proactive tracking of assets, reducing the risk of loss or theft and ensuring assets are returned to their designated locations.

Rfxcel: Implemented a traceability UHF-RFID system enables the ability to trace the history and location of components throughout the manufacturing process, aiding in quality control and compliance.

Many applications of RFID by GAO can be found here:

GAO RFID Systems & Hardware for Spacecraft Manufacturing

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including spacecraft manufacturing.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humility, vibration and panic button:

GAO’s BLE technology is suitable for many industries, including spacecraft manufacturing:

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including spacecraft manufacturing:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including spacecraft manufacturing:

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including spacecraft manufacturing:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

The RFID systems by GAO are highly popular for clients in spacecraft manufacturing:

Physical asset or operational equipment tracking system:

Assets that can be effectively tracked using GAO’s technologies include:

- Satellite Component Testers:Specialized equipment for testing and evaluating the performance of individual satellite components, such as communication systems, power systems, and sensors.

- Rocket Engine Test Stands:Used to test and evaluate rocket engines for thrust, performance, and reliability.

- Precision Machining Equipment:CNC (Computer Numerical Control) machines, lathes, milling machines, and other precision machining equipment used for manufacturing spacecraft components with high precision and accuracy.

- Spectroscopy Equipment:Used for analyzing the composition and properties of materials used in spacecraft manufacturing, ensuring quality control and material compatibility.

- Test and Measurement Instruments:Equipment such as oscilloscopes, spectrum analyzers, signal generators, and power supplies used for testing, measuring, and analyzing various electrical and electronic parameters during spacecraft manufacturing and testing.

- Optical Systems: Optical equipment such as telescopes, spectrometers, and interferometers used for aligning and testing optical components and systems in spacecraft.

- Test Ranges: Dedicated outdoor areas or facilities for conducting rocket and spacecraft testing, including launch pads, testing sites, and tracking stations.

- Robotics and Automation Systems:Robotic arms, automated assembly lines, and robotic testing systems used for efficient and precise spacecraft assembly, testing, and handling.

People or workers tracking system:

Physical asset or operational equipment tracking system:

Personnel or people access control system:

Parking or vehicle control system:

GAO Has Served Spacecraft Manufacturing Extensively

GAO’s products and technologies have helped its customers in spacecraft manufacturing to achieve success in additive manufacturing/3D printing, digital twin, automation, cube Sats, electric propulsion, Internet of Things (IoT).

GAO RFID Inc. has deployed RFID, BLE and IoT projects for many companies in spacecraft manufacturing, including many in its various divisions such as:

- Launch Vehicles: Companies that design, manufacture, and launch rockets and other vehicles that transport spacecraft into space.

- Satellites: Companies that design, manufacture, and operate satellites for various purposes, such as communications, remote sensing, and scientific research.

- Spacecraft Components: Companies that specialize in the production of individual components and subsystems for spacecraft, such as propulsion systems, communication systems, and guidance systems.

- Ground Systems: Companies that design and manufacture ground-based systems that support spacecraft operations, such as tracking and control systems, communication networks, and data processing systems.

- Payload Integration: Payload integration involves the integration of satellite payloads onto launch vehicles. This division ensures proper integration, testing, and compatibility of the payloads with spacecraft or rocket.

- Rocket Manufacturing: Rocket manufacturing involves the design, development, and production of launch vehicles used to deliver satellites, payloads, and crewed missions into space. This division includes the manufacturing of rocket engines, stages, and associated systems.

Here are some of the leading companies in spacecraft manufacturing industry.

MacDonald,Dettwiler

and Associates (MDA)

Magellan Aerospace

Israel Aerospace

Industries (Israel)

COMDEV International

NEPTUNE Canada

Space Flight

Laboratory (SFL)

Maxar Technologies

Blue Canyon Technologies

Firefly Aerospace

SpaceX

Sierra Nevada

Corporation

Orbital Sciences

Corporation

Aerojet

Rocketdyne

Relativity Space

Virgin Galactic

United Launch

Alliance (ULA)

Ball Aerospace

Millennium Space Systems

Honeybee

Robotics

Maxar Technologies

Astrobotic Technology

Firefly Aerospace

Nanoracks

Rocket Lab